From Niche to Norm

A heat pump is not new invention but very much a matured technological feat: Even though the Austrian engineer Peter von Rittinger built the first device in the mid-1850s, the heat pump’s most important milestone for the modern day was achieved in 1938. At that time, in the town hall of Zurich, a 100 kW system was installed which successfully used river water to heat a building for the first time and which could also be used for cooling.

Despite this long history, heat pump technology has undergone a significant transformation over the past 20 years.

Higher Efficiency Through Better Components

The efficiency of heat pumps has improved significantly over the past two decades, primarily due to advances in the refrigeration cycle and its components. Electronic expansion valves now ensure precise control of refrigerant flow, thereby reducing energy consumption. Modern compressors — specifically designed for refrigerants such as propane — also operate more quietly and efficiently.

A key step was the spread of inverter control, which ensures that the heat pump runs smoothly and according to demand. This improves efficiency by at least 10 percent compared to older, clocked systems. At the same time, improved lubricants were developed that optimize operation and extend service life.

In case of heat exchangers—the components that absorb and release heat—both the size and distribution of the refrigerant have been optimized1. These measures prevent performance losses of up to 20 percent and increase the efficiency factor. Today’s heat pumps are therefore significantly more economical than their predecessors, noticeably lowering heating costs and reducing environmental impact.

Numbers Prove the Progress

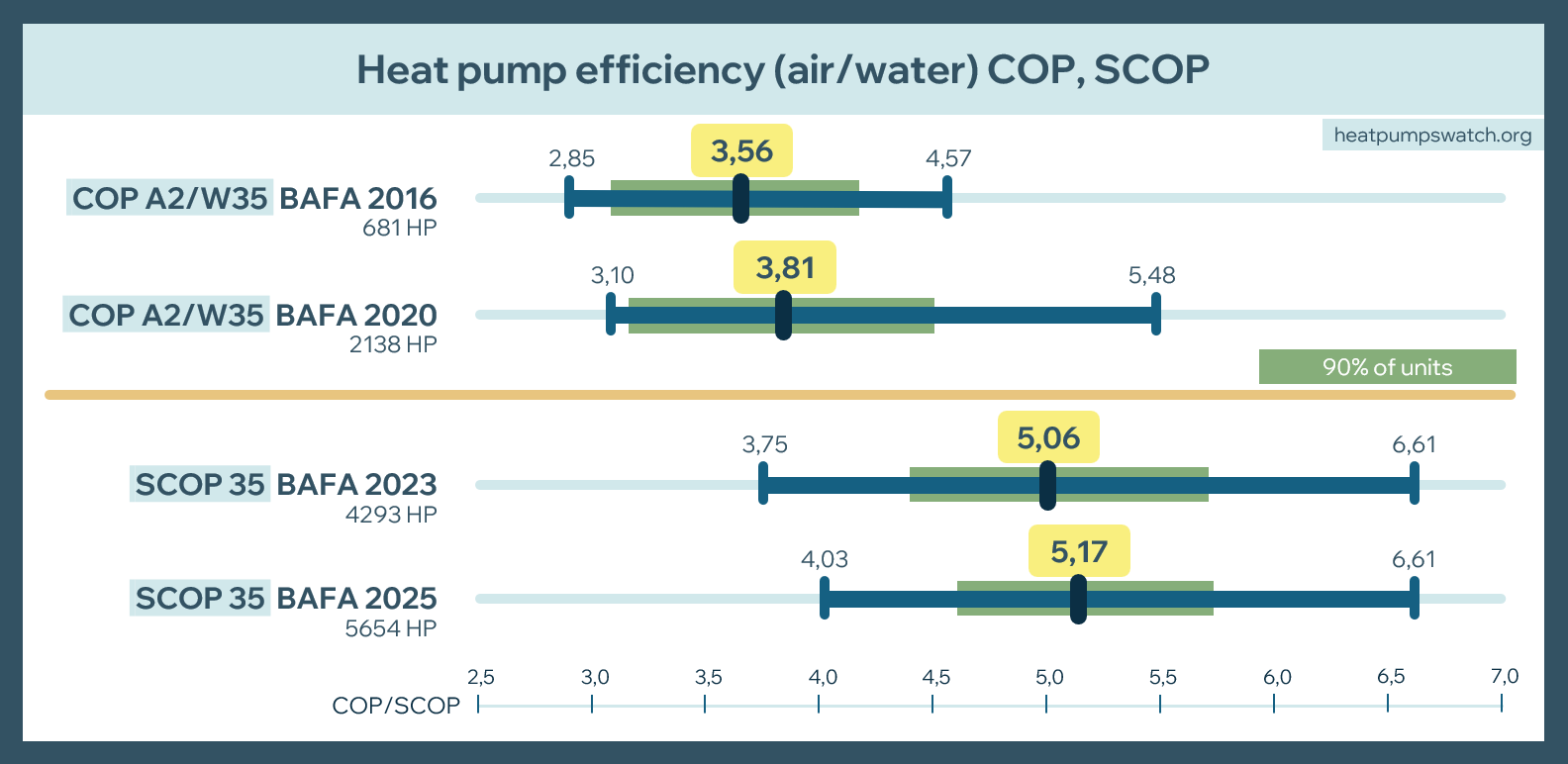

The following chart illustrates efficiency improvements in absolute terms. The analysis is based on BAFA lists (lists of subsidized heat pumps with verified performance and efficiency data) from 20162, 20203, 20234, and 20255. Since the evaluated parameters have changed, the years are only comparable in pairs.

In 2016 and 2020, Coefficient of Performance (COP) values were analyzed for the operating point A2/W35, while in 2023 and 2025, the Seasonal COP (SCOP) value was used, derived from the ηs (ETAs) value at 35 °C. In the previous years, only modulating heat pumps were evaluated. In all cases, only systems with a thermal capacity of up to 20 kW were included.

The graph shows respective minimum, maximum, and average efficiency values, as well as a green area that symbolizes the efficiency range in which 90 percent of the models fall.

Average efficiency increased between 2016 and 2020, with the largest gains observed in the maximum values. Strikingly, the best models achieve significantly higher efficiencies than 90 percent of the others, indicating that these top-performing systems are still relatively rare on the market.

In 2023 and 2025, the minimum values improved the most, suggesting that the least efficient systems have disappeared from the market. Maximum values remained stable, while average values increased slightly.

The improvement in laboratory-measured values is also reflected in real-world field tests, as is discussed in more detail in Part 2 of this series.

Technical Measures for Noise Optimization

In addition to higher efficiency, heat pumps have become significantly quieter over the past 20 years. While older units often produced noise levels comparable to loud conversations or passing cars, modern systems typically operate at 35–55 dB(A) — similar to a refrigerator or soft background music6.

This improvement has been achieved through several technical advances: Inverter technology ensures that the heat pump continuously adjusts its output. This means that it does not operate with loud start-up and shutdown cycles, but rather runs evenly and quietly, which also reduces vibrations.

New fans with aerodynamically shaped blades cause less airflow noise. Casings have been improved with sound-absorbing and damping materials that capture most of the noise7. Installation practices have also evolved — special mounts and rubber buffers now reduce vibrations and prevent transmission to the building structure.

Overall, these measures have reduced sound levels by 10–15 decibels. Since this corresponds to roughly halving the perceived loudness, acceptance in residential areas has greatly increased.

Rising Application of Natural Refrigerants

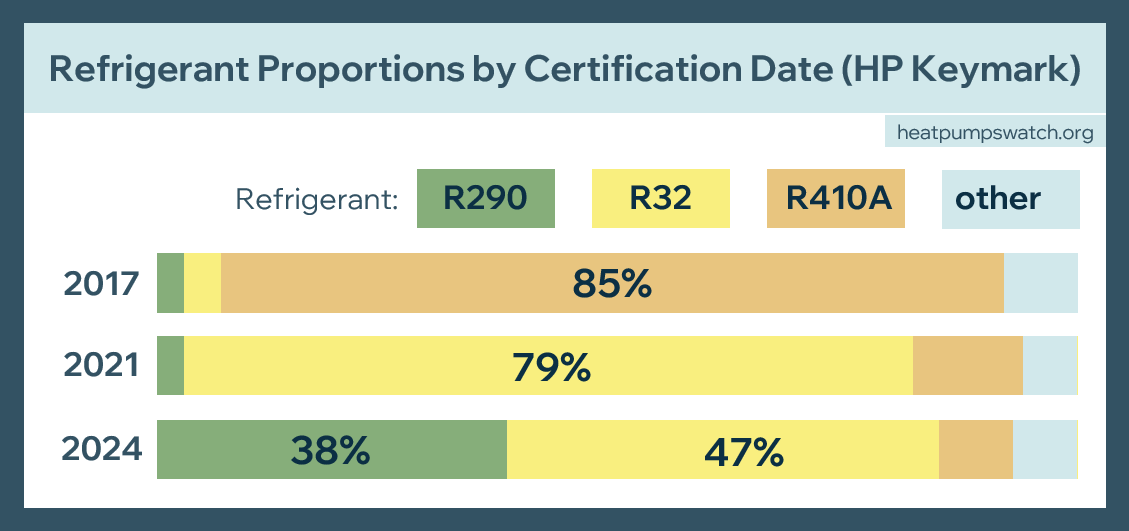

A key development trend in refrigerants, evident in certification data from the HP Keymark database, is the accelerated switch toward more sustainable alternatives. The EU F-Gas Regulation compels manufacturers to drastically reduce the use of high-GWP (Global Warming Potential) fluorinated gases. In response, low-GWP alternatives have gained significant importance: R32, with a GWP of 675, serves as a transitional solution, while the natural refrigerant R290 (propane), with a GWP of only 0.18, sets the standard for long-term climate-neutral technology.

Initially, R410A (GWP 2088) was the dominant refrigerant in heat pumps. As shown in the diagram, R410A has been increasingly replaced by low-GWP alternatives. The first major step was the adoption of R32, which reached a 79 percent market share in 2021. Since 2022, however, it has been rapidly displaced by R290 (propane), whose share rose continuously to 38 percent in 20249.

Suitable even for Older Buildings

The suitability of heat pumps for older buildings has improved significantly in light of two closely linked factors. First, thanks to increased efficiency, modern systems achieve performance ratios of 0.1 and higher even at low outdoor temperatures (see Part 2 of the series). Second, the maximum achievable flow temperatures have increased, making heat pumps suitable even for partially or non-renovated buildings. These higher temperatures are made possible primarily by the use of propane (R290) as a refrigerant, whose market share continues to grow.

The Intelligent Heat Pump

Over the past 20 years, the digitalization of heat pumps has evolved fundamentally. Intelligent control systems with self-learning algorithms now automatically optimize operation. By analyzing usage patterns and incorporating weather forecasts, they achieve significant efficiency gains.

Integration with other building technologies has become standard: heat pumps now work seamlessly with photovoltaic systems and battery storage. According to the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW), this enables self-consumption rates of home-produced energy of up to 70 percent.

Dynamic electricity tariffs can be automatically utilized to shift operation to low-cost periods, reducing operating costs by up to 30 percent. Cloud-based systems allow remote maintenance and predictive servicing through continuous monitoring, while smartphone apps provide users with full control and transparency at all times.

Moreover, grid-supportive operation of heat pumps benefits the entire energy system.

Appealing Design Instead of Industrial Aesthetics

Heat pumps are not only more efficient and quieter but also more visually appealing. Many modern models are no longer eyesores but can be integrated harmoniously into architectural designs. Over the past 20 years, design has shifted from purely functional, industrial appearances toward modern, minimalist aesthetics. Driven by market demand, heat pumps have evolved from utilitarian, clanky boxes into architectural features or discreet façade elements.

Why Now is the Right Time

Will heat pumps continue to improve in the future? Certainly — but major leaps are unlikely. Very efficient and quiet models are already available on the market, and the current technological goal is mainly to raise average performance levels.

Future development will focus on lowering production costs, using fewer or alternative materials, increasing durability, and simplifying and accelerating installation. Another key aspect for the future is better integration into the overall energy system and improved communication with other devices such as photovoltaic systems, electric storage units, and the power grid. This will allow heat pumps to contribute more effectively to load flexibility and deliver financial benefits to operators.

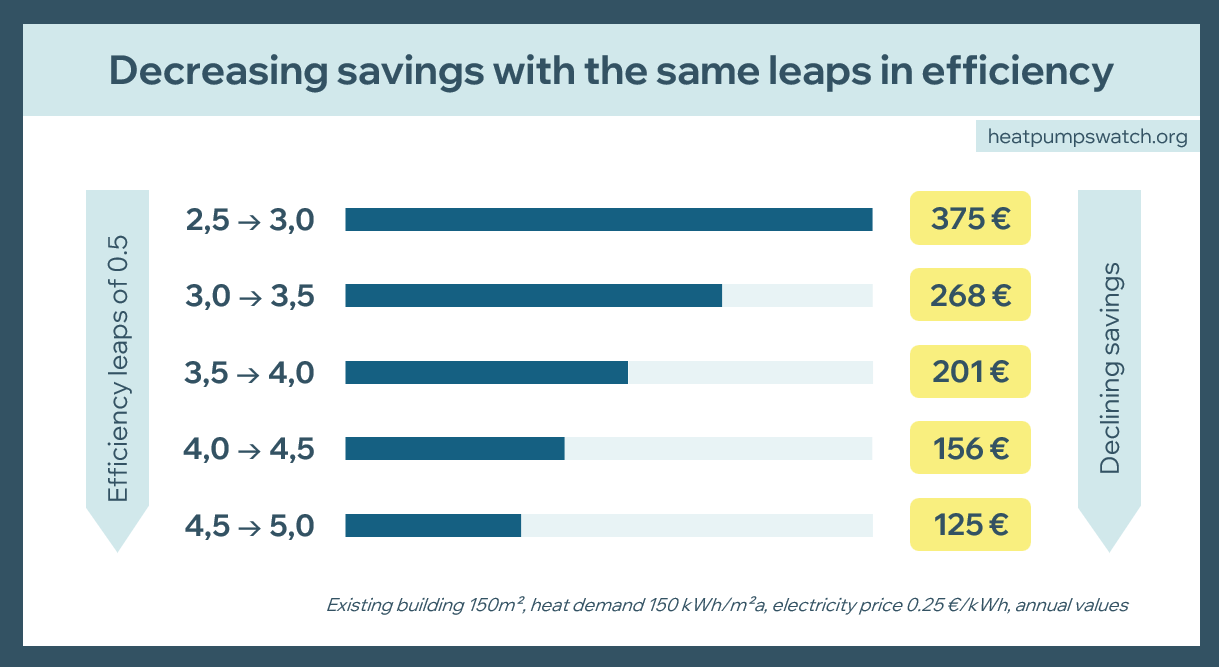

It is worth noting that the benefits of efficiency improvements do not grow linearly. Most savings occur at lower starting efficiency levels, not at already high ones. The following chart illustrates this relationship.

An increase in efficiency by 0.5 points initially (from 2.5 to 3.0) results in annual savings of 375 Euro. The same increase from 4.5 to 5.0 — already at a high efficiency level — yields only one-third as much, around 125 Euro.

Simply put: it is not worth waiting. Heat pump technology is already mature, and further efficiency improvements will become ever less significant for end users from a financial perspective. It’s also worthwhile from an environmental point of view: every heat pump not only saves operating costs but also CO₂ emissions. In some markets, such as Germany, the timing is especially favorable because subsidies remain (for now) very attractive.

In the next episode of our series, we will examine the important topic of “Heat Pumps in Existing Buildings” and clarify the differences between theory and practice, as well as the common myths and facts.

All Episodes

Episode 1: Beyond the Noise: What the Heat Pump Truly Means for Our Society

Episode 2: 20 Years of Field Studies Prove: Heat Pumps Efficient in Existing Buildings

Episode 3: From Niche to Norm: 20 Years of Progress in Heat Pump Technology

Episode 4: The Heat Pumps Fact Check: Ten Myths Scientifically Disproven

Episode 5: Efficiency Knows no Age: Heat Pumps in Buildings from 1826 to Present Day

Episode 6: Heat Pumps in Multi-Family Buildings: The Key to Urban Decarbonization

Episode 7: Hybrid Heat Pump Systems

Episode 8: Operating Costs: Heat Pumps Already Outperform Gas Heating Systems Today

Episode 9: Thousands of Heat Pumps Models on the Market: How to Find the Right One for Me?

Episode 10: Heat Pumps and AI: A Perfect Match?

- Kærn, M. R. (2011). Analysis of flow maldistribution in fin-and-tube evaporators for residential air-conditioning systems. Technical University of Denmark. DCAMM Special Report No. S132 ↩︎

- Bundesamt für Wirtschaft und Ausfuhrkontrolle (BAFA) (2016). Erneuerbare Energien. Wärmepumpen mit Prüfnachweis (Stand: 11/2016). Eschborn. ↩︎

- Bundesamt für Wirtschaft und Ausfuhrkontrolle (BAFA) (2020). Wärmepumpen mit Prüf- / Effizienznachweis. Heizen mit Erneuerbaren Energien (Stand: 14.12.2020). Eschborn. ↩︎

- Bundesamt für Wirtschaft und Ausfuhrkontrolle (BAFA) (2023). Liste der förderfähigen Wärmepumpen mit Prüf-/Effizienznachweis. Bundesförderung für effiziente Gebäude – Einzelmaßnahmen (BEG EM) Zuschuss (Stand: 27.10.2023). Eschborn. ↩︎

- Bundesamt für Wirtschaft und Ausfuhrkontrolle (BAFA) (2025). Liste der förderfähigen Wärmepumpen mit Prüf-/Effizienznachweis. Bundesförderung für effiziente Gebäude – Einzelmaßnahmen (BEG EM) Zuschuss (Stand: 16.09.2025). Eschborn ↩︎

- Bednar, T., Hinterseer, S., Kaseß, C., Natiesta, T., Neusser, M., Reichl, C., Rieberer, R., Wagner, P., & Waubke, H. (2022). IEA Wärmepumpentechnologien (HPT) Annex 51: Akustische Emissionen von Wärmepumpen (Schriftenreihe 2022-30). Österreichische Forschungsförderungsgesellschaft (FFG). Verfügbar unter: https://nachhaltigwirtschaften.at/resources/iea_pdf/schriftenreihe-2022-30-iea-hpt-annex51.pdf ↩︎

- International Journal of HVAC&R (2022). The Impact of Vibration Damping on Noise Reduction in Air Source Heat Pumps.” International Journal of HVAC&R, Vol. 19, Issue 4. ↩︎

- Intergovernmental Panel on Climate Change (IPCC), Sixth Assessment Report (AR6), Working Group I: The Physical Science Basis, Kapitel 7, Tabelle 7.SM.7 (2021). ↩︎

- Lämmle, Manuel, and Leroy Tomás. “Datenbasierte Auswertung der technischen Kenndaten von zertifizierten Wärmepumpen.” HLH: Lüftung, Klima, Heizung, Sanitär, Gebäudetechnik 76.4 (2025): 26-31. ↩︎